Phil & Sebastian Coffee Roasters

Phil & Sebastian Coffee Roasters - Decaf

This coffee was decaffeinated at a facility called DESCAFESOL, which is actually the first and only coffee decaffeination facility in Colombia. Here, the coffee goes through a unique water and ethyl acetate (EA) process. The water is from the nearby mountains and the EA is naturally sourced from sugar cane.

ETHYL ACETATE DECAF PROCESS

Ethyl Acetate is a bit of scary "chemical" sounding name, but it helps to understand a bit of the basic chemistry.

Ethyl Acetate is an "ester" and it's derived from the reaction Ethanol (pure alcohol) and Acetic Acid (pure vinegar). Both of these inputs are of course consumable by us! In our case, the Ethanol comes from the fermentation of sugar cane molasses (the sugar cane is grown in Colombia). During the decaf process the beans are heated with steam to open the pores, then an Ethyl Acetate wash is applied. This is one case where water (the universal solvent) is not the best choice.

Caffeine is very stubborn and difficult to remove and it's more soluble in Ethyl Acetate than water. Additionally, Ethyl Acetate boils off at only 77 degrees C, so it can be completely removed by washing the beans in hot water after the wash. The Ethyl Acetate is long gone before the coffee is ever roasted, but if any residual ever existed it would vanish in the roasting process, which heats the beans to over 200 degrees C.

It is also useful to note that Ethyl Acetate is naturally occurring in wine. As you can imagine from the above chemistry, it's produced when the grapes are fermented. Ethyl Acetate at the right concentration is actually sought after in wine as it contributes to a wine's perceived "fruitiness".

Two other steps, that make our decaf a cut above even other Ethyl Acetate processed coffees, are that we select high quality coffee to decaffeinate (most decafs are the bottom of the barrel in terms of quality), as well, the coffee is always fresh-harvested as we get fresh shipments from Colombia two-times per year!

-

DECAFFEINATION: Naturally processed at DESCAFESOL using mountain water and sugar cane

-

STORAGE: Green coffee frozen to preserve freshness

-

ESPRESSO BREWING PARAMETERS: 18.8g in, 40g out, 33 sec, 201 °F, 125 psi

- Total Dissolved Solids (TDS): 20 ppm

- Bicarbonate (HCO3): 18 ppm or less (most important)

- Calcium (Ca): 5 ppm

- Magnesium (Mg): 2 ppm

- Sodium (Na): 2 ppm

Couldn't load pickup availability

Pickup currently unavailable at Head-Office

Pairs well with

If you have any questions, you are always welcome to contact us. We'll get back to you as soon as possible, within 24 hours on weekdays.

-

Shipping Information

Use this text to answer questions in as much detail as possible for your customers.

-

Customer Support

Use this text to answer questions in as much detail as possible for your customers.

-

FAQ’s

Use this text to answer questions in as much detail as possible for your customers.

-

Contact Us

Use this text to answer questions in as much detail as possible for your customers.

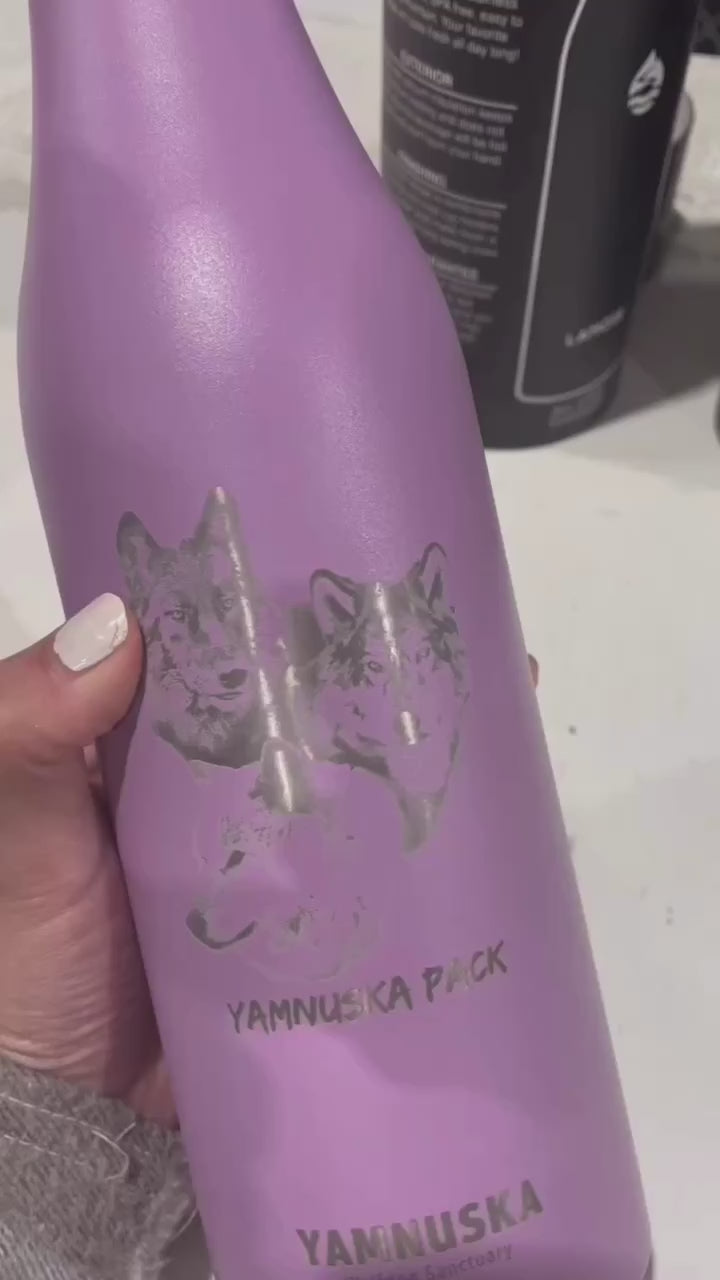

Make It Your Own

Celebrate personalization by transforming everyday items into unique reflections of you. From custom engravings to stylish designs, make the ordinary uniquely yours.

More Than Drinkware

Your LAMOSE product isn't just a container; it's a daily companion that carries your story, reminding you of the moments, people, and places that matter most. Whether you're an adventurer inspired by Canadian landmarks, a thoughtful giver offering a practical yet personal gift, or a change-maker choosing sustainability, each sip connects you to something meaningful.

Crafted with Heart, Made for You

At LAMOSE, our small Canadian team is dedicated to helping you share your story through personalized, thoughtfully engraved gifts crafted with care. Every order is designed and engraved in-house, ensuring a truly special gift for your loved ones to cherish daily. Committed to sustainability, we are proud members of 1% for the Planet, supporting environmental causes and promoting reusable, eco-friendly alternatives to single-use plastics. Thank you for visiting LAMOSE—let’s create something meaningful together!

FAQs

Please read our FAQs page to find out more.

Do LAMOSE products come with a warranty? If so, what does it cover?

All LAMOSE products come with a lifetime warranty. This covers any manufacturing defects in the material or workmanship under normal use and maintenance. Please note, this doesn't cover damage caused by accidents, inappropriate use, or wear and tear.

What materials are LAMOSE products made from?

LAMOSE products are made from high-quality, food-grade 18/8 stainless steel, renowned for its strength, durability, and resistance to rust and corrosion. Our lids are made from BPA-free plastic with a silicone seal to ensure a tight fit and prevent leaks. Our materials are carefully selected to ensure they are safe, sustainable, and able to keep your drinks at the perfect temperature.

How long will LAMOSE drinkware keep my drinks hot or cold?

Our LAMOSE drinkware is designed with advanced thermal technology. For our hydration and beer can collections, cold beverages can stay chilled for up to 24 hours. Hot beverages in our coffee collection can stay warm for up to 12 hours. However, the actual duration can vary based on the starting temperature of the drink, the outside temperature, and how often the container is opened.

Are LAMOSE products dishwasher safe?

While our LAMOSE drinkware is made from durable stainless steel, we recommend hand washing all our products to maintain the integrity of the insulation and the longevity of the custom engravings. Using the dishwasher may affect the insulation properties and could lead to fading of the personalized designs over time.

Can I microwave my LAMOSE drinkware?

No, LAMOSE products should not be microwaved. Our drinkware is made of stainless steel, which is not safe to put in the microwave. Microwaving can damage both the product and the microwave.

How should I clean my LAMOSE drinkware?

To clean your LAMOSE drinkware, hand wash with warm, soapy water. Rinse thoroughly after cleaning and leave it open to air dry. Avoid using bleach or abrasive cleaners to maintain the integrity of your drinkware and its custom design.